As lean practices have evolved over the decades, more and more business across a smattering of industries have adopted these principles in an attempt to streamline their operations.

While the list of lean practitioners continues to grow as years pass, not everyone who stakes a lean claim is seeing consistent benefits. Slagging productivity, high employee turnover or increasing lead times are all signs that managers may need to re-examine their lean practices.

These kinds of lags in seeing the benefits can sometimes be attributed to not practicing lean principles faithfully. How can a manager tell if their operation is truly and consistently lean? Here are a handful of tell-tale signs.

Adopting a New Mindset

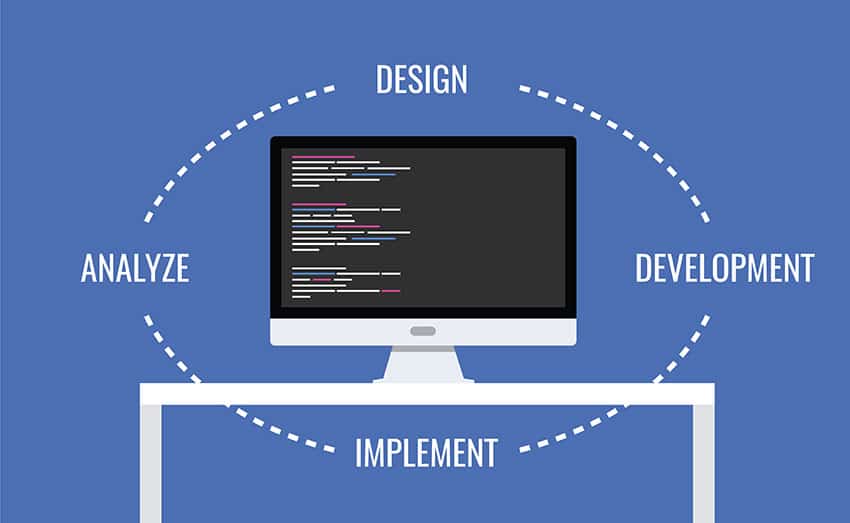

This is an area where many lean operations stumble, especially after first attempting to implement streamlined practices. After learning about lean, many managers want to jump on the bandwagon without dedicating the time and resources to properly train staff and management on lean thinking and processes. Without the ability to look at their jobs through a lean lens, these principles won’t mean much.

To be blunt, it’s easy to toss a new set of tools into the mix. What’s truly difficult is adopting a new mindset while using those fancy new tools.

Solving Problems That Matter

Another sign that your company is practicing lean consistently is a focus on resolving issues of significance.

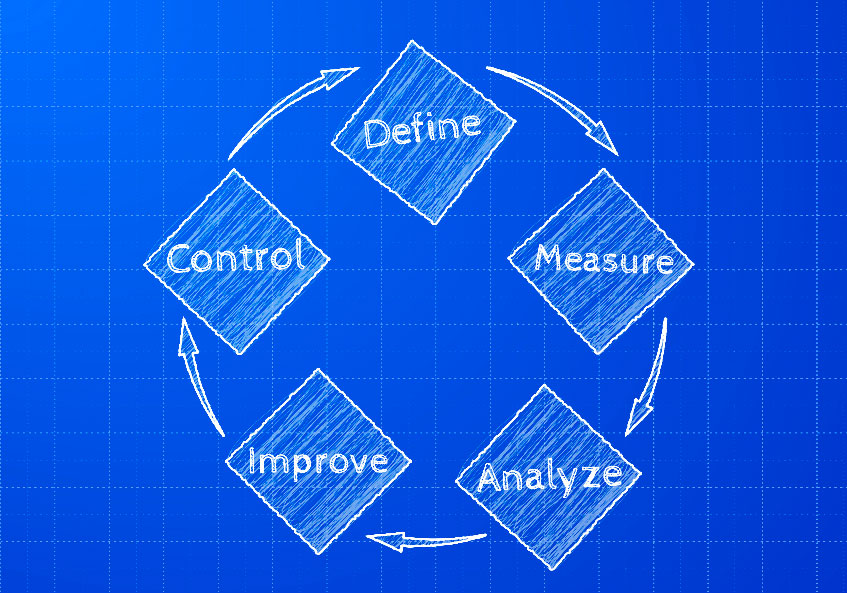

Lean has an almost scientific approach to solving problems, and this should be applied to problems that actually matter to your organization. Don’t waste your time applying the principle for something minor — instead, push issues that could help your organization move forward through this filter.

For example, instead of using lean to solve an issue like a constantly disorganized supply closet, focus on streamlining the process behind hiring new employees. Solving these kinds of issues will return value to your operation, and effectively boost productivity and/or boost your bottom line.

Fostering an Improvement Culture

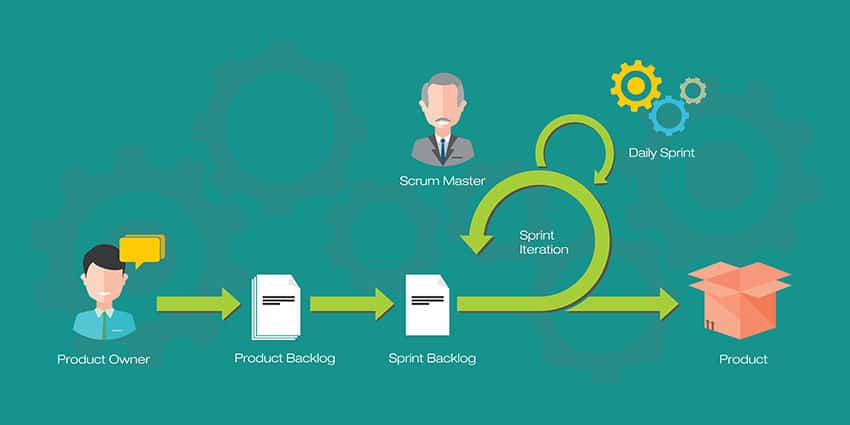

Are employees or customers regularly speaking up about things that could be changed? If so, then that could be a sign that your organization is fostering a culture of continuous improvement.

Managers who truly value lean processes will see the value in these comments rather than writing them off. When managers see these kind of comments as valuable feedback rather than complaints, this is a massive step toward encouraging engagement with your organization’s continuous improvement processes. Normally, they’re identifying processes or issues they need to be corrected rather than whining about something irrelevant.

When staff members aren’t afraid to speak up and offer their ideas, they’re more engaged and invested in the success of the company. And this kind of engagement is invaluable in moving the improvement process forward and achieving company-wide success.