Boosting profitability is an ingoing battle for every company. They tackle innumerable obstacles daily in order to create a leaner, meaner revenue-creating machine.

Really, this is the end-goal for almost every organization: creating streamlined, efficient processes in order to boost their bottom line.

It’s always a struggle to incrementally become more competitive, but adopting the principles of lean management is one method of charting out specific ways to get there. Whether you’re in manufacturing, service, healthcare or telecommunications, it’s possible to integrate the lean principles into your practices and potentially boost your efficiency and profitability.

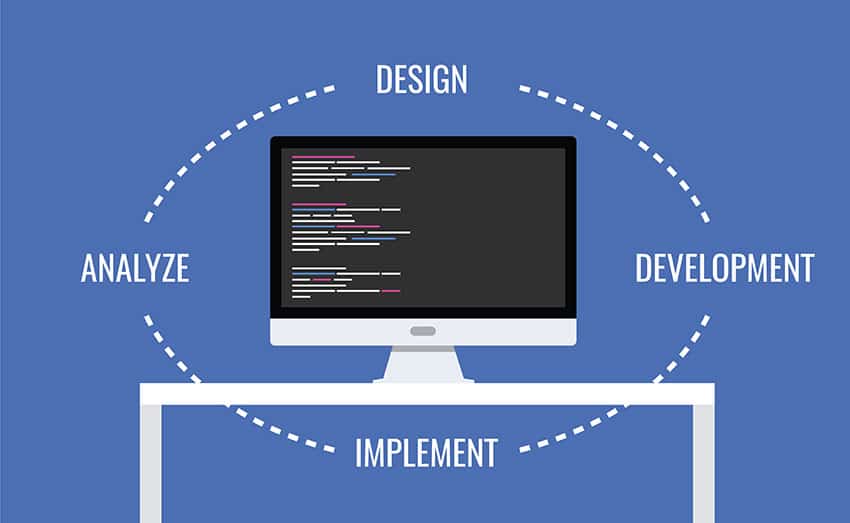

Measure Your Current Level of Efficiency

It’s important to take the time to analyze the status quo of your workflows. How efficient are your processes currently? And what are the areas that could be improved?

Getting a sense of every facet of the business and where certain processes are lagging can make the improvement process flow much more smoothly later on.

Involve Your Employees

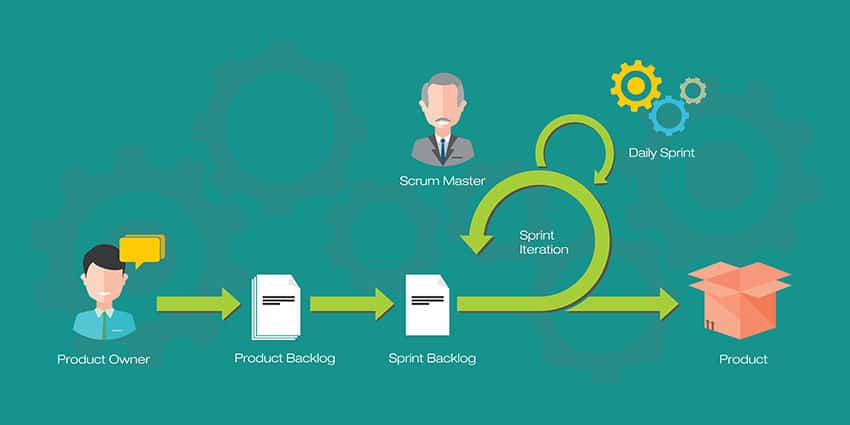

During and after the analyzation process, it’s integral to get your employees involved. That means getting everyone from front-line workers all the way up to C suite executives in on the assessment.

Talking to employees on every level ensures you as a lean manager get a complete sense of the production processes in your company, as well as anecdotes and valuable input on where things could be improved.

Kaizen specifically, which is one lean management technique, calls for workers to be broken up into smaller groups to brainstorm ideas on ways to add value and cut costs.

Rethink How You Measure Success

While it’s almost intuitive to rely on numbers like revenues and profits to dictate how a company’s success is measured, it may be time to rethink the metrics you’re using.

Instead, it may be more telling to sit down and calculate the value created by your organization. The value-added index is calculated by looking at how much your company produces (whether that’s in products or services) per hour of direct labour.

Rather than relying on gross profit margins, this is likely a more telling number to determine just how efficient your organization currently is, and can give you a strong indication of where there may be some room for improvement.

Make Changes Incrementally

Once you’ve done your analysis and discovered gaps or flaws in your processes, it’s time to create an improvement strategy.

While it may be tempting to start from scratch, it’s actually often wiser to make incremental changes over time. Not only will staff and workers respond better to more gradual changes, but improvements made over time can be closely monitored. Lean managers can ensure each step in the improvement process is implemented successfully before moving on to the next step.